- LOGISTICS

- LOGISTICS

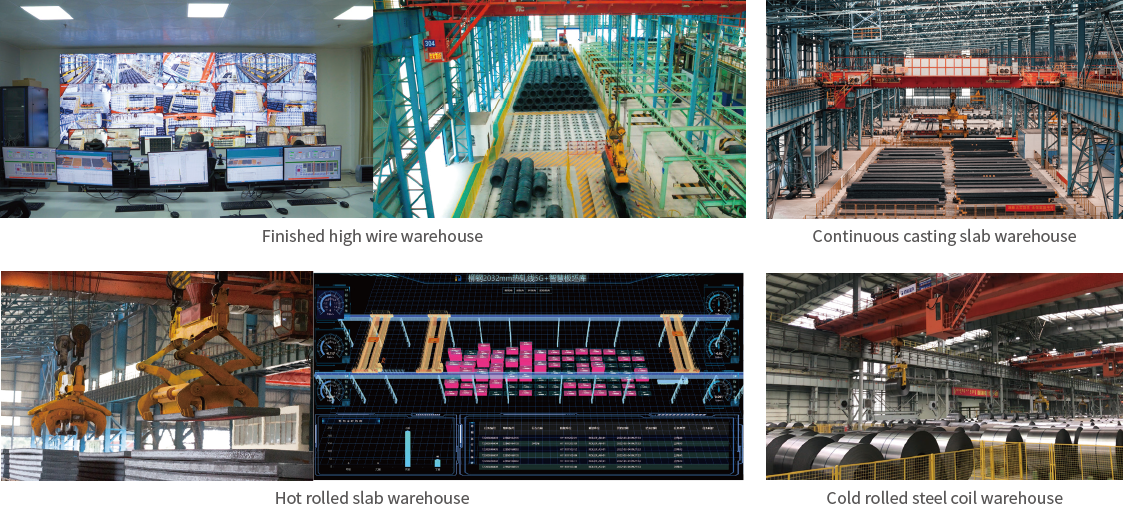

- Technologies such as AI recognition, anti-swing control, positioning system and 5G wireless transmission and 3D intelligent warehouse management system are used to allow intelligent warehouse dispatching and management and unmanned crane operation. Current situation of traditional cranes and warehousing relying on manual operation and command is changed to reduce labor costs, significantly improve warehousing and logistics efficiency, reduce material loss and allow unmanned, information-based and intelligent warehousing

- Technologies such as AI recognition, anti-swing control, positioning system and 5G wireless transmission and 3D intelligent warehouse management system are used to allow intelligent warehouse dispatching and management and unmanned crane operation. Current situation of traditional cranes and warehousing relying on manual operation and command is changed to reduce labor costs, significantly improve warehousing and logistics efficiency, reduce material loss and allow unmanned, information-based and intelligent warehousing

- AI identification

- Anti-swing control

- Positioning system

- Positioning system

- Crane dispatching system

- Intelligent warehouse management system

- Intelligent expansion module

- Automatic crane system

- Ground management system

- Intelligent database management system is a 3D operating terminal with 1:1 live display

- Intelligent warehouse management system applying modular design, with high scalability

- Parameterized settings for device configuration and dispatching rules, allowing independent decisions by users

- The system integrates functions such as intelligent algorithms, time path optimization, auto- matic obstacle avoidance, virtual two-layer saddle, multi-axis linkage

- System interface optimization design, easy operation, high efficiency, easy use and maintenance

- Increase storage area utilization by ≥ 25%

- Reduce operators 4 persons/crane

- Improve worke fficiency Reduce labor intensity Eliminate safety hazards

- Achieve zero lifting loss Reduce internal friction in enterprises Reduce costs and increase efficiency

- Use of information technology and intellectual technology in logistics management

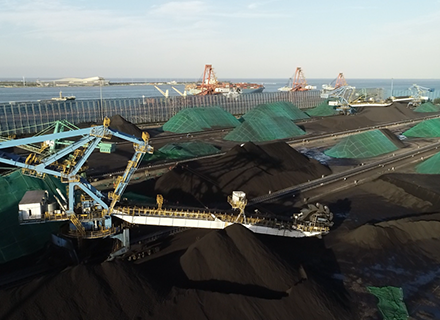

- To present, the intelligent warehouse management system of Bestpower Intercontrol has been used in 45 storage areas, and over 100 cranes have been renovated and put into use.

System Composition

System Characteristics

Economic Benefits

Cases

Address:Bestpower Intercontrol, Building 2, No. 18, JiancaichengDonglu, Xisanqi, Haidian District, Beijing, China

Postal code:100096

E-mail:bp@bpintelcontrol.com

Telephone:+86 10 8296 5880

Fax:+86 10 8292 8991

Address:Bestpower Intercontrol, Building 2, No. 18, JiancaichengDonglu, Xisanqi, Haidian District, Beijing, China

Postal code:100096

E-mail:bp@bpintelcontrol.com

Telephone:+86 10 8296 5880

Fax:+86 10 8292 8991

Scan the QR code to

learn more

WeChat Official Account

WeChat Official Account

WeChat Video Account

WeChat Video Account

Tik Tok

Tik Tok